Basic electrical safety on construction sites

Incident

23 August 2016

An apprentice electrician sustained an electric shock while working at a major construction site. The apprentice was not undertaking specific electrical work at the time but was in close proximity to electrical cables. The apprentice was cable tying electrical cables in a cable tray. While undertaking this work the apprentice came into contact with a cable that was energised and received a shock.

Contributing factors

The cables had been previously checked by the apprentice and de-energised, however the circuit was re- energised by persons unknown. The site was busy with a number of contractors undertaking work in the vicinity including electrical work. The lock out of the electrical circuit was not maintained and workers undertaking related works were not aware the circuit had been re-energised.

Action required

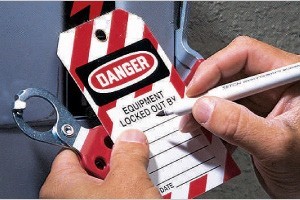

Basic electrical safety should be observed in regard to the energising or de-energising of electrical circuits and cable. Circuits and equipment should be definitively tagged out for de-energised work. High visibility tags and physical locks should be used to inform and warn that electrical power is isolated. Where multiple workers are involved each should put their individual tag/lock in place to ensure that circuits are not re-energised when others are still working. Tags should not be removed except by an authorised person or the owner of the tag.

Identify energy sources:

- Identify the circuit/s to be locked out or isolated

- Determine lockout methods.

Notify all affected employees:

- At construction sites with a large workforce you may need to have special communication methods and permits or approvals.

- Trace all systems to locate and lock out energy sources. Always look for other possible energy sources. De-energize electrical circuits by disconnecting the power source from the circuit

Install lockout devices:

- The lockout devices attached to one system should not prevent access to the controls and energy-isolating devices of another system

Tagging:

- Attach a durable tag to your lock. The tag should identify the worker’s name, the worker’s employer, the date and time of lockout, the work area involved, and the reason for the lockout

- A tag in itself offers no guarantee that a machine or system is locked out. It simply provides information.

Verify zero-energy state:

- Test the system to ensure that all electrical components are de-energized and de-activated, including interlocking and dependent systems that could feed into the system, either mechanically or electrically.

Perform the task, carry out and complete the work assignment.

Re-energise the circuit, remove lock and tags and inform other workers.

In view of the risk of electrocution associated electrical hazards PCBU’s should consider arranging refresher CPR training for electricians on a regular basis.

Further information

For further information contact WorkSafe ACT on 13 22 81 or email WorkSafe@act.gov.au.

This Alert contains information emerging during an investigation by WorkSafe ACT into the mentioned incident at the date of this report. The information contained in this report does not necessarily reflect the final outcome of WorkSafe’s views or proposed actions with respect to this incident. WorkSafe ACT does not warrant the information in this report is complete or up-to date and does not accept any liability to any person for the information in this report, or its use.

On this page